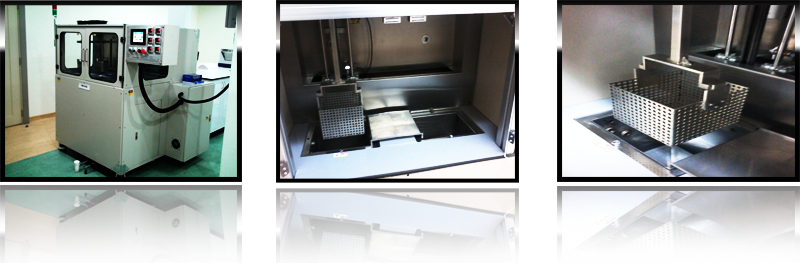

- The Automatic Thermocycling dipping machine is designed for simulation of oral temperature changes. The sample is immersed cyclically in baths of hot, warm and cold fluids. The machine is controlled by programmable logic controller (PLC) system with a touch screen as the interface for users. A simulation cycle was built as a mobile arm with a basket of one or more profiles, where the user can select two or three types of temperature. All six tanks are independent of each other and can be controlled via a touch screen.

- The UML-V1 is a CNC lathe machine is the first Malaysian Made CNC Lathe. It is designed and developed by researchers and academicians of AMMP Centre, University of Malaya, Malaysia. The machine was designed to incorporate industry standard requirements and features while at the same time is user friendly, especially for beginner-level users.

- Error

-

- You are not authorised to view this resource.